MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.

The spindle of a machine-tool is one of the most critical elements in ensuring the precision of cutting tool rotation, whatever the cutting parameters, and transmitting cutting forces efficiently.

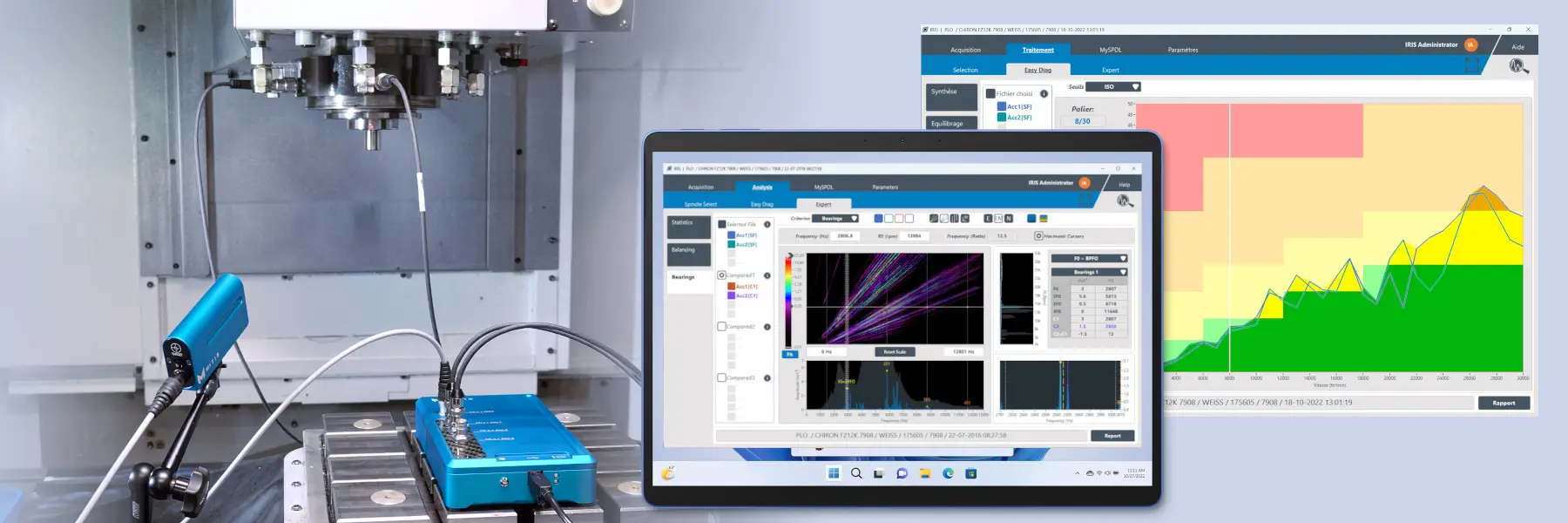

IRIS is a portable system for preventive maintenance of spindles, based on precise and comprehensive vibration diagnostics.

Unbalance and other rotational anomalies: evaluate dynamic spindle balancing over its entire speed range

Bearing wear: accurately identify the condition of spindle bearings and anticipate failure

Intuitive interface and handling, can be used on any type of machine

Fast installation and measurement, clear and comprehensive diagnostics

Advanced analysis tools, MITIS support for diagnostic assistance

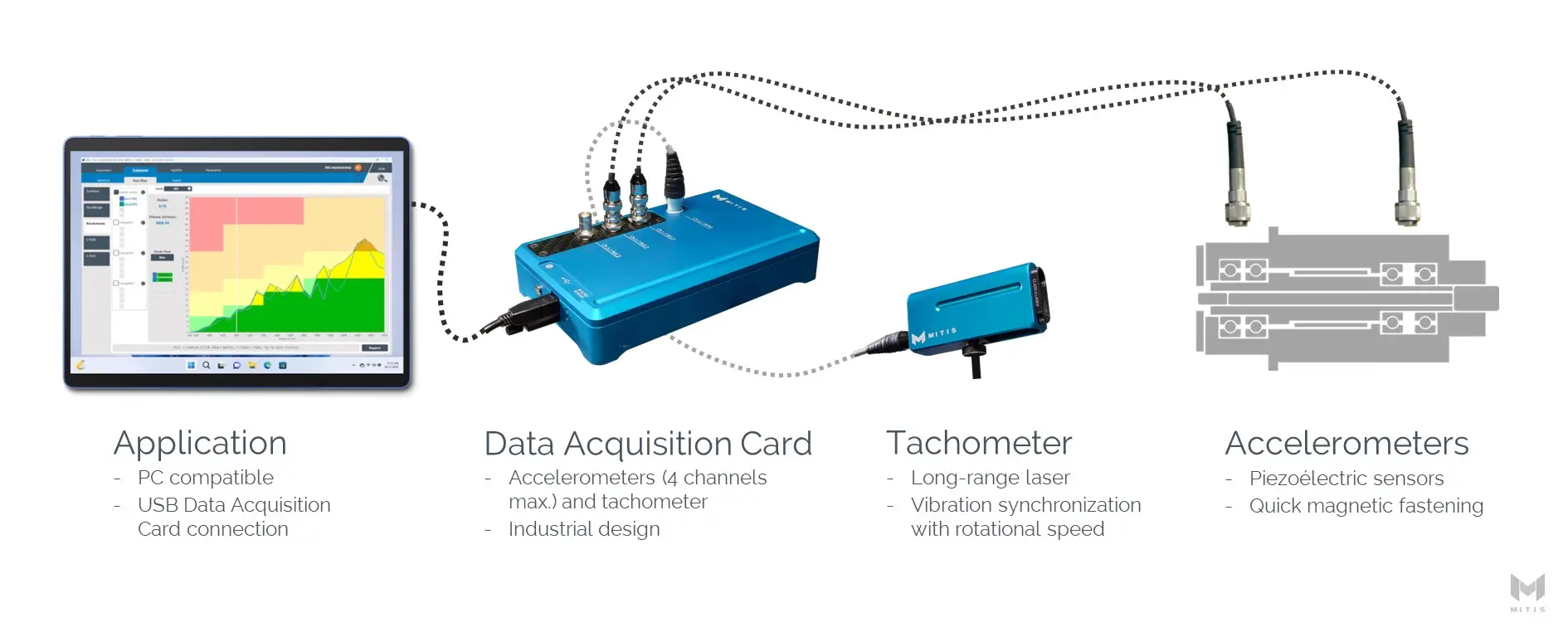

Quick and easy to install measurement chain;

robust, high-performance sensors and acquisition cards for use in production environments.

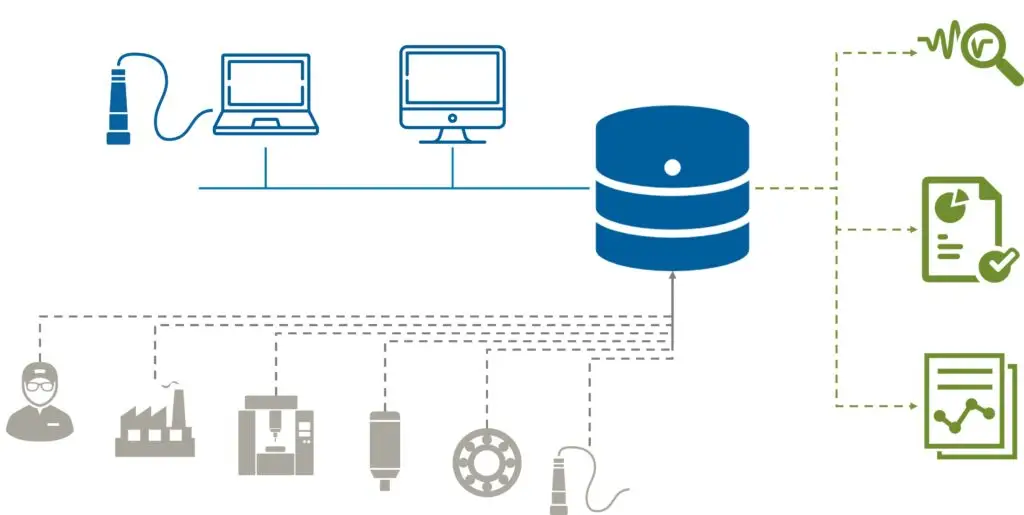

IRIS enables you to reference each of your spindles with its characteristics and the context in which it was used (manufacturer and type, bearings, machine, production site, etc.), for optimum traceability throughout its life cycle.

The IRIS system is based on an SQL database that enables users to centralize all the information they need to monitor their spindles, as well as the vibration measurements made.

The application gives you access to all relevant data for analysis and monitoring:

Depending on your needs and requirements, IRIS offers several vibration analysis tools, from the simplest and most synthetic to the most advanced.

The “Easy Diag” synthesis tool gives, for each accelerometer, the maximum value of the balancing and bearing condition criteria, and the rotation speed at which this value was reached.

The “Easy Diag” synthesis tool gives, for each accelerometer, the maximum value of the balancing and bearing condition criteria, and the rotation speed at which this value was reached.

The associated colors correspond to the monitoring thresholds (good, satisfactory, unsatisfactory, unacceptable). These thresholds are those specified in ISO 17243 or can be adapted by the user.

This graph shows the evolution of balancing and bearing condition criteria for each sensor and over the entire range of spindle speeds.

This graph shows the evolution of balancing and bearing condition criteria for each sensor and over the entire range of spindle speeds.

The Easy Diag tool enables you to compare vibration signatures:

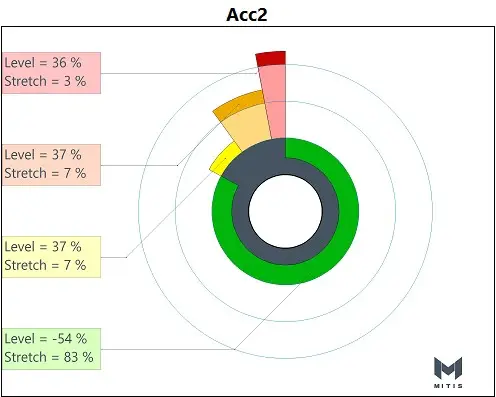

The IRIS VIEW graph allows you to identify at a glance how thresholds for a given criterion have been exceeded (balancing or bearing condition) across all spindle signature speeds.

The IRIS VIEW graph allows you to identify at a glance how thresholds for a given criterion have been exceeded (balancing or bearing condition) across all spindle signature speeds.

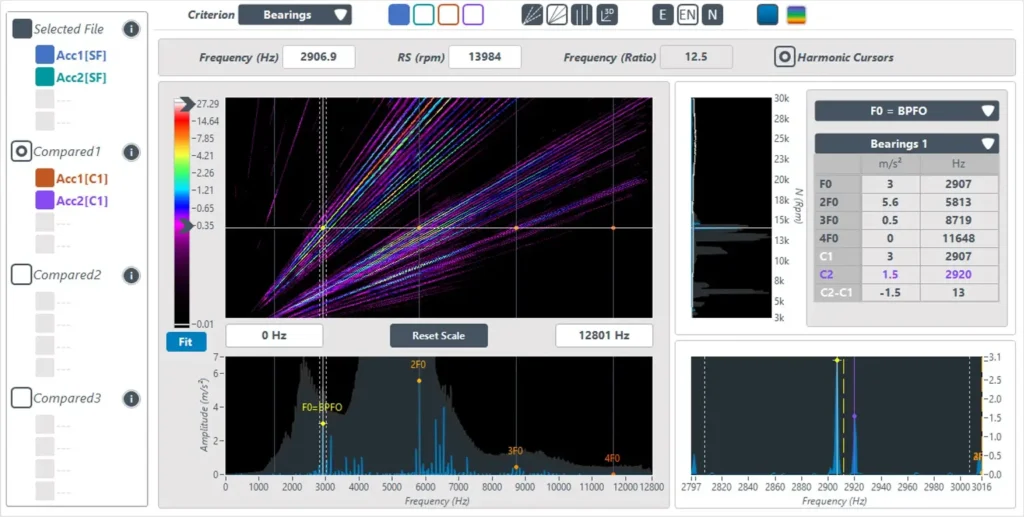

The 2Di spectrogram gives the frequency content of the vibration signal over the entire spindle signature. It can be calculated in terms of vibration speed (mm/s) or acceleration (m/s²).

The 2Di spectrogram gives the frequency content of the vibration signal over the entire spindle signature. It can be calculated in terms of vibration speed (mm/s) or acceleration (m/s²).

Characteristic components are automatically identified on the spectrum:

Spindle designers or repairers, CNC machine-tool manufacturers, machinists: a common language to describe the condition and behavior of spindles.

Reference of the Vibratory Drilling process, specialist in axial machining processes and designer of drilling spindles, MITIS is also recognized for its expertise in the measurement and study of vibrations in machining.

With over fifteen years’ experience in the field, the MITIS team can help you with :

Would you like to know more about our vibration diagnosis solutions for spindles?

Contact us at +33 2 40 59 24 21 or leave us a message:

MITIS, entreprise de technologies innovantes installée depuis 2012 à Bouguenais (Nantes), est la référence du procédé de Perçage Vibratoire, solution d’excellence pour optimiser les performances en production d’usinage.